Jigs & Fixtures — Precision Tools for Reliable and Safer Production

Custom-Built Jigs and Fixtures for Manufacturing, Assembly & Safety

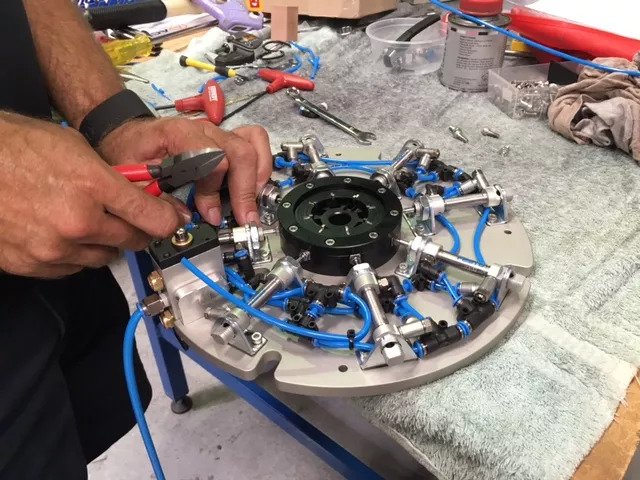

At Oz-Models, we design and manufacture precision jigs and fixtures that help streamline production, improve accuracy, and enhance workplace safety.

Our team has decades of experience creating reliable, well-engineered setups for assembly, machining, inspection, testing — and Occupational Health & Safety (OHS) applications.

From ergonomic handling jigs to safety guards and alignment tools, we help clients reduce operator strain, minimise risk, and make everyday manufacturing tasks easier, safer, and more efficient.

Our Capabilities

Custom jigs and fixtures for manufacturing, testing, quality control, and safety improvement

CNC-machined components for precision alignment, repeatability, and durability

Prototyping and low-volume production of specialised tooling

Workholding and inspection fixtures for machining, metrology, and process consistency

Design-for-use optimisation - ergonomic, efficient, and easy to maintain

OHS-focused tooling - ergonomic jigs, guards, and assistive fixtures designed to reduce manual strain, improve safety compliance, and support safer workplace practices.

Why Choose Oz-Models

✅ Tailored design - we engineer every jig or fixture to match your process, tolerances, and safety needs

✅ In-house machining & assembly - total control, accuracy, and fast turnaround

✅ 30+ years of toolmaking expertise - practical, proven solutions that last

✅ Collaborative design support - work directly with our engineers to solve production and OHS challenges

✅ Safety-minded innovation - many of our jigs and fixtures are built specifically to reduce operator strain, improve ergonomics, and help clients meet OHS standards

✅ Proudly Australian-made - quality and reliability you can depend on

From concept sketches to final machining, every step is handled locally in our Hornsby workshop.

Applications

We’ve designed and built jigs and fixtures for:

Machining and drilling operations

Product assembly lines

Electronics and small component testing

Plastic and metal part inspection

Prototype or low-volume manufacturing setups

Occupational Health & Safety solutions - including ergonomic handling jigs, safety guards, and positioning fixtures to minimise operator strain and improve workplace safety

The Oz-Models Difference

Because we’re both toolmakers and manufacturers, we don’t just design for looks - we design for function.

Every jig and fixture is engineered to make your work faster, more consistent, and more profitable.

Let’s Build Your Next Fixture

Bring us your parts, drawings, or even just an idea. We’ll design and manufacture a jig or fixture that fits your needs perfectly — practical, reliable, and built to last.

📞 02 9476 8214

📧 wally@ozmodels.net.au

📍 Hornsby, NSW